In 1988 SSD (subsequently Eurotherm Drives and now Parker-Hannifin) introduced the LINK drive system product line. The LINK drive system was a market disruptor. When LINK was first introduced, most existing drive systems used analog technology. Custom discrete boards were sold by drive manufactures to perform PID functions, summing and basic math needed for coordinated drive system control. Speed reference signals between drives were discrete hardwired analog references. Most operator stations that interfaced to drives consisted of discrete pushbuttons, potentiometers, analog meters. The machine logic interface from a central PLC to the drive system was hardwired and there was no distributed remote I/O for field process inputs. LINK completely changed the integrated drive system paradigm.

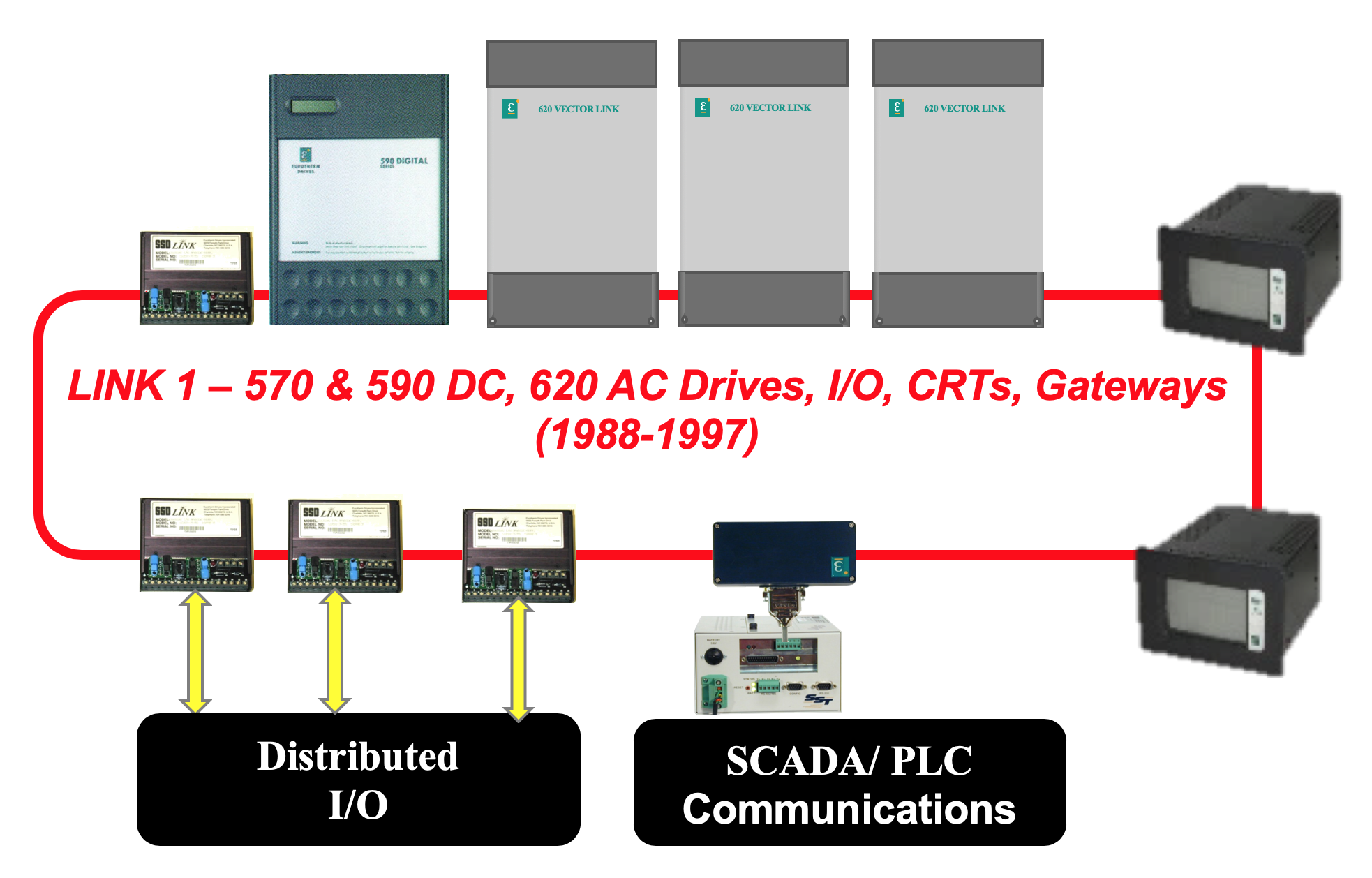

LINK was a fully digital, distributed coordinated drive system that utilized noise immune fiber optic peer-to-peer 2.7 MBaud communications between its nodes. LINK nodes originally were DC drives, operator CRTs, analog and digital remote I/O modules, with data interfaces for SCADA systems and PLCs. Later, AC vector drives were added to LINK. If you needed to add processing power for complex functions you simply added a LINK EEPROM processing within another node. LINK’s Configuration Editor programming software was object oriented that made it intuitive to use by control engineers and service personnel. You did not need to be a software programmer to use LINK effectively. Drive software function block macros were designed to create a control library for loadcell tension trim, dancer position trim, cascade draw, unwind and winders, electronic line shafting and torque regulation applications. These standard control macros ensured standardization between projects for design, startup preparation and maintenance support. Key LINK benefits were less costly installations, fasters startups, improved control and improved support. These system attributes made LINK the likely choice of many OEMs and end users drive systems.

LINK systems were the gold standard of their era but, some 30+ years after inception, all LINK components are no longer fabricated by Parker Hannifin. This leaves end users that still have operational LINK lines extremely susceptible to failures of difficult to find replacement component parts.

MCS can greatly assist you in the replacement of your existing LINK drives systems. Depending upon the type and age of your LINK system, sometimes this upgrade can be done in a staged approach, sometimes it is best for a wholesale change-out of the entire drive system. In either case, we can assist in the supply of needed components, engineering, installation and commissioning services to make the upgrade as straight forward and cost effective as possible to dramatically improve the reliability and support of your operation.