PLC

The PLC (Programmable Logic Controller) was created in the 1960s as a means to replace hard-wired relay systems with a more maintainable, flexible, environment suitable alternative. Today, PLCs still replace relay machine interlock functions but also serve as means to monitor and/or control line process inputs and outputs (I/O) for temperature, pressure, flow, length, position, and motion.

PLCs have also advanced in their use for safety functions. In fact, there is an entire category of PLCs called Safety PLCs. Safety PLCs are designed to fail in a predictable/ safe manner. They achieve this objective through redundant microprocessors, that eliminate the need for safety relays to create redundancy. No safety system ever designed is 100% foolproof. Ultimately, what level of safety system redundancy is required for a given application is best handled on a case by case basis, in consultation with a skilled system integrator.

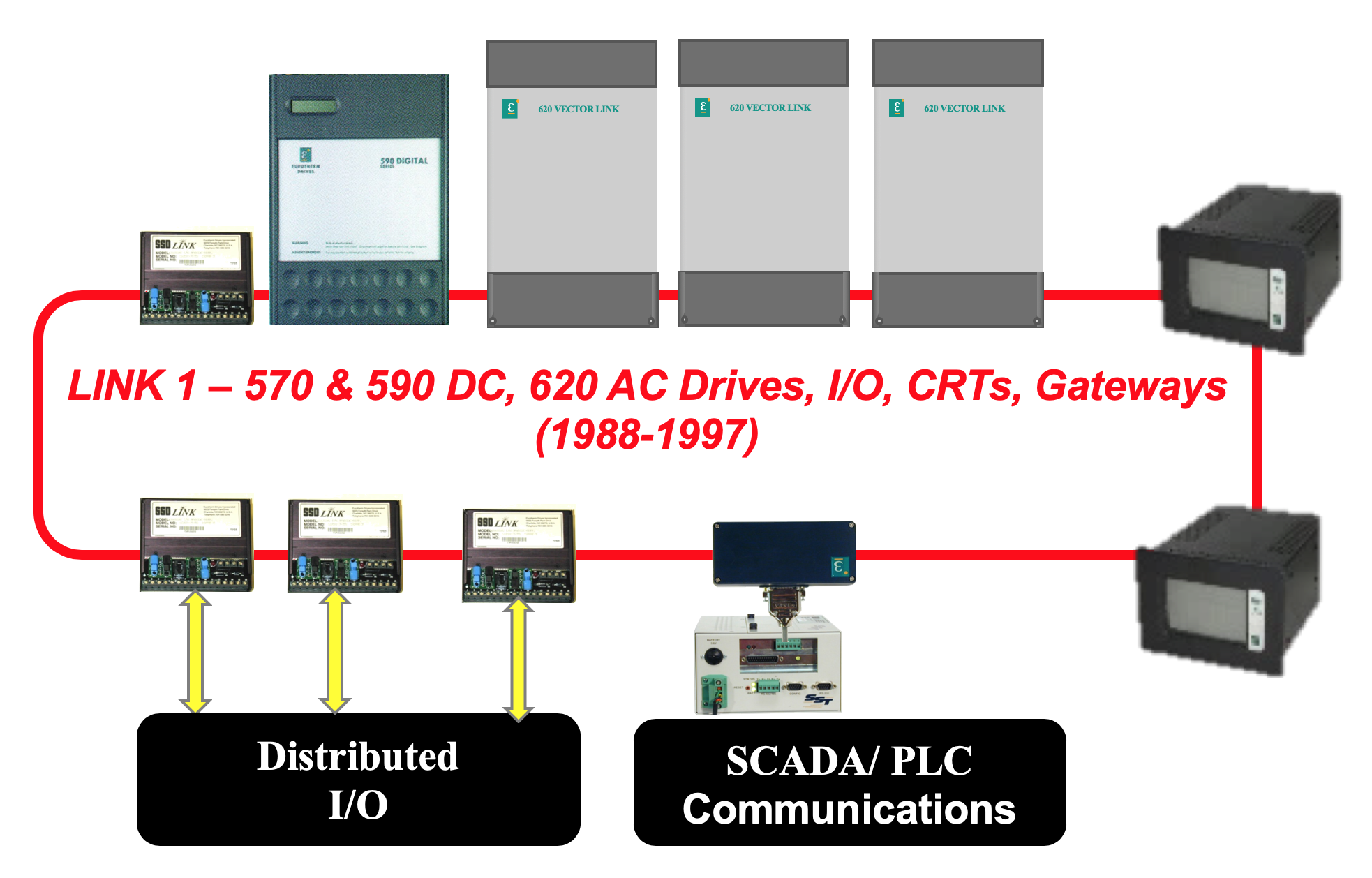

PLCs also act as distributed data communication centers throughout an industrial facility. In effect, they can serve as machine state and process data transducers for HMIs, SCADA, data historians and quality/enterprise computer systems. We regularly upgrade, provide anew and service a wide variety of PLC brands and platforms. We also make PLC brand recommendations based upon the application needs and your facility automation standards and goals. We look forward to working with you on your next PLC project.