Data Management

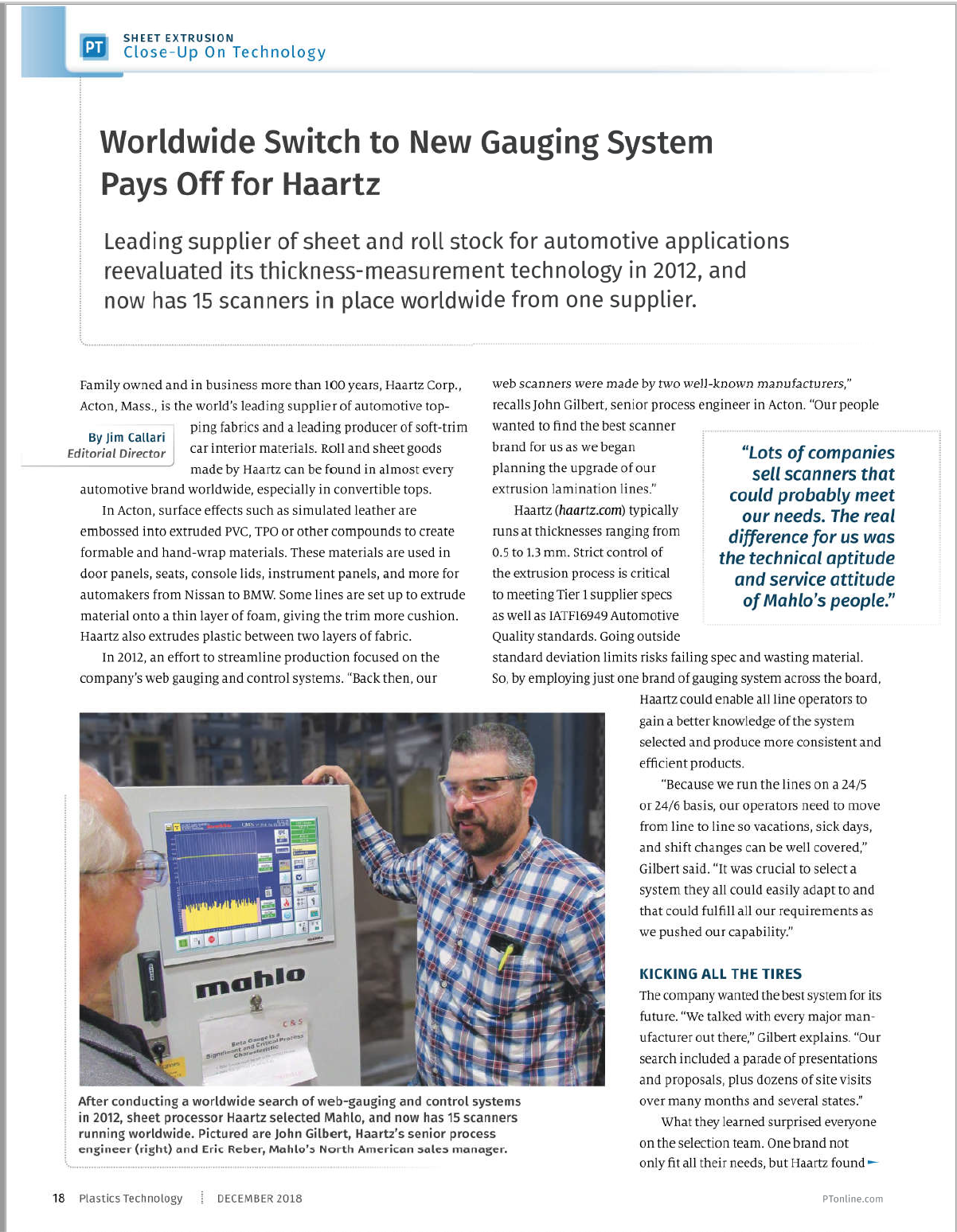

Industrial manufactures of roll and sheet goods have always focused on maximizing product throughput while maintaining quality standards. Today’s manufacturers are also faced with providing quality certification standards (e.g. ISO, GAMP) and doing deeper data dives into the process to further qualify the products they produce through business analytics. A big challenge in this certification effort is how to gather quality and process data from the various onsite measurement and control equipment, and then consolidate that data so it is efficient and effective to use by the organization’s different departmental personnel. We are expert in the retrofit of older web-handling lines with new measurement and control equipment that act as data communication transducers to identified drivers of process value. Once we implement a means to gather meaningful process and quality data, we have proven solutions to show you how to make best use of that data. Our recommended solutions always comply with fully supported industrial standards, while meshing with the existing data framework of your facility.

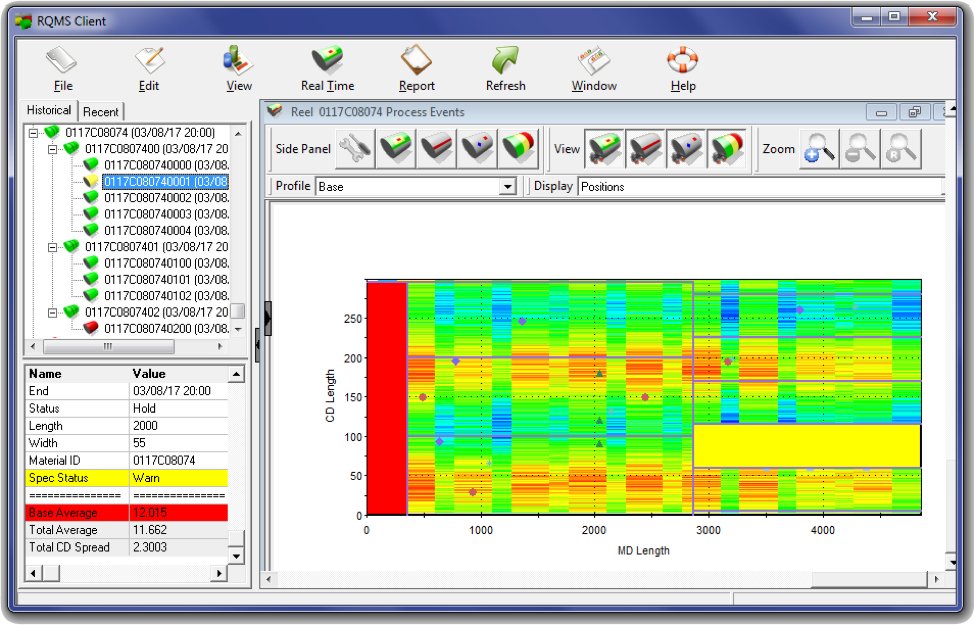

Roll Certification, Disposition and Yield Reports

Projects we support include:

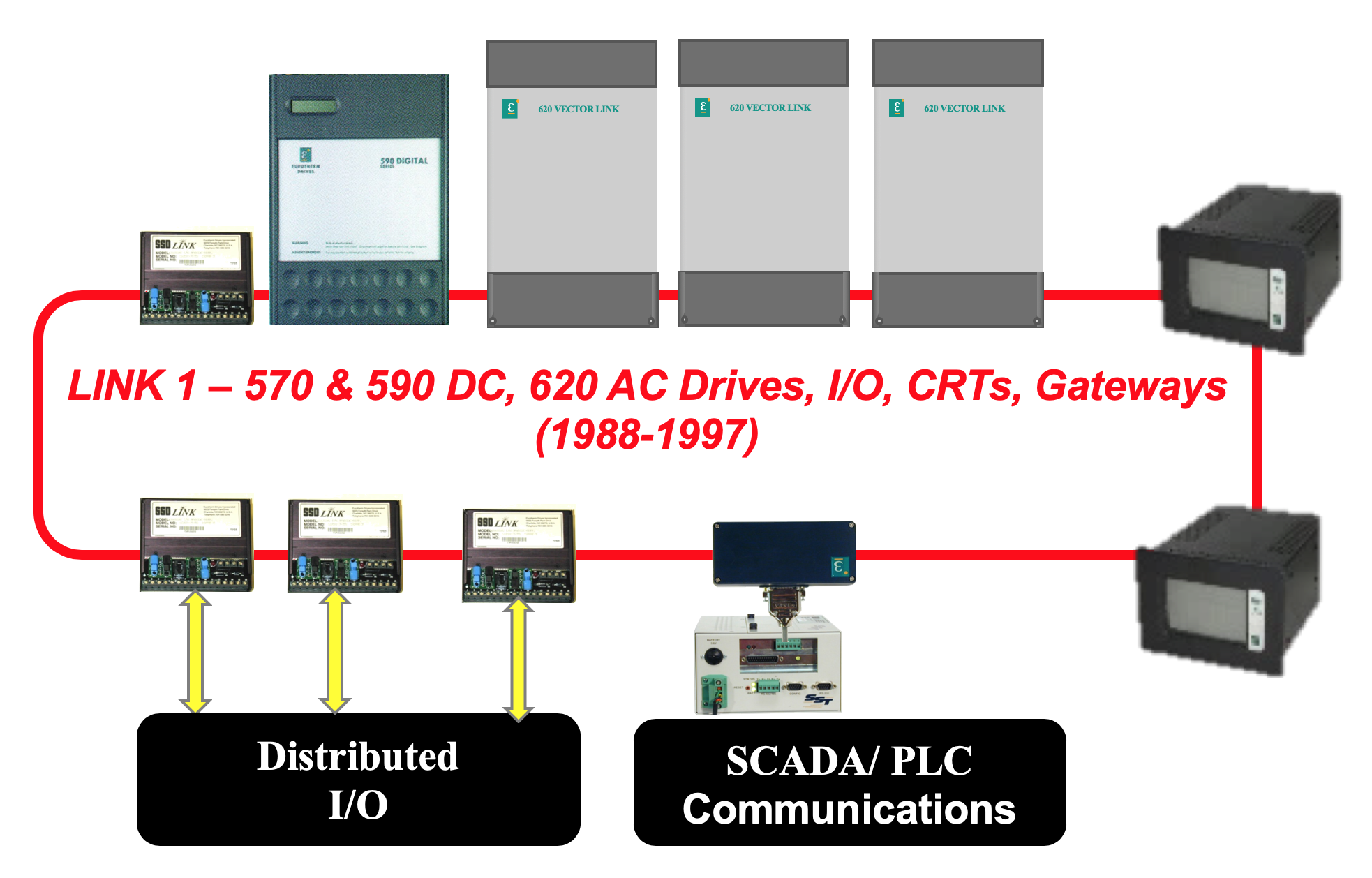

Roll Quality Management Systems – Acquire, archive and register by roll length and cross directional position data for: gauging system arrays, web inspection defect roll maps, process parameter historians (e.g. web speeds, tensions, temperatures, viscosity, flow rates, pressure, etc.) and other miscellaneous on-line communicating devices of interest.

Measurement Certifications - Correlate on-line measurements with Laboratory Information Management System (LIMS)

Roll Tracking Systems of Line-to-Line Parent/Sibling Rolls – Register and track each roll’s physical properties throughout the facility’s incoming material, converting, slitting, storage and shipping cycle.

Auto-Stop on Defects – Model, edit and execute educated product disposition decisions based upon comprehensive and accurate roll data - even for multi-pass product formations.

End of Roll Auto-Stopping – Eliminate scrap left on unwound/wound cores.

Yield Tracking – Track waste or scrap down to the inch.

Set-Length Control – Control the precise length of rolls produced.

Stretch and Shrink Monitoring – Know real-time distortion of flexible webs.

Roll Yield Tracking – Account for stretch/shrink, sample and splice material loss between multiple lines to determine actual end product yields.

Automatic Storage and Retrieval Warehouse Systems – Track rolls in and out of warehouse storage.

Integration to Business Systems – provide middleware between real-time process systems and transaction-oriented business systems including MES and ERP environments.

Consolidated Gauging Cross Direction Arrays & Web Inspection Defect Positions Displayed by Slit Lane

Please contact us to discuss the optimization of your facility’s roll/sheet process and quality data needs.