Automatic Web Inspection

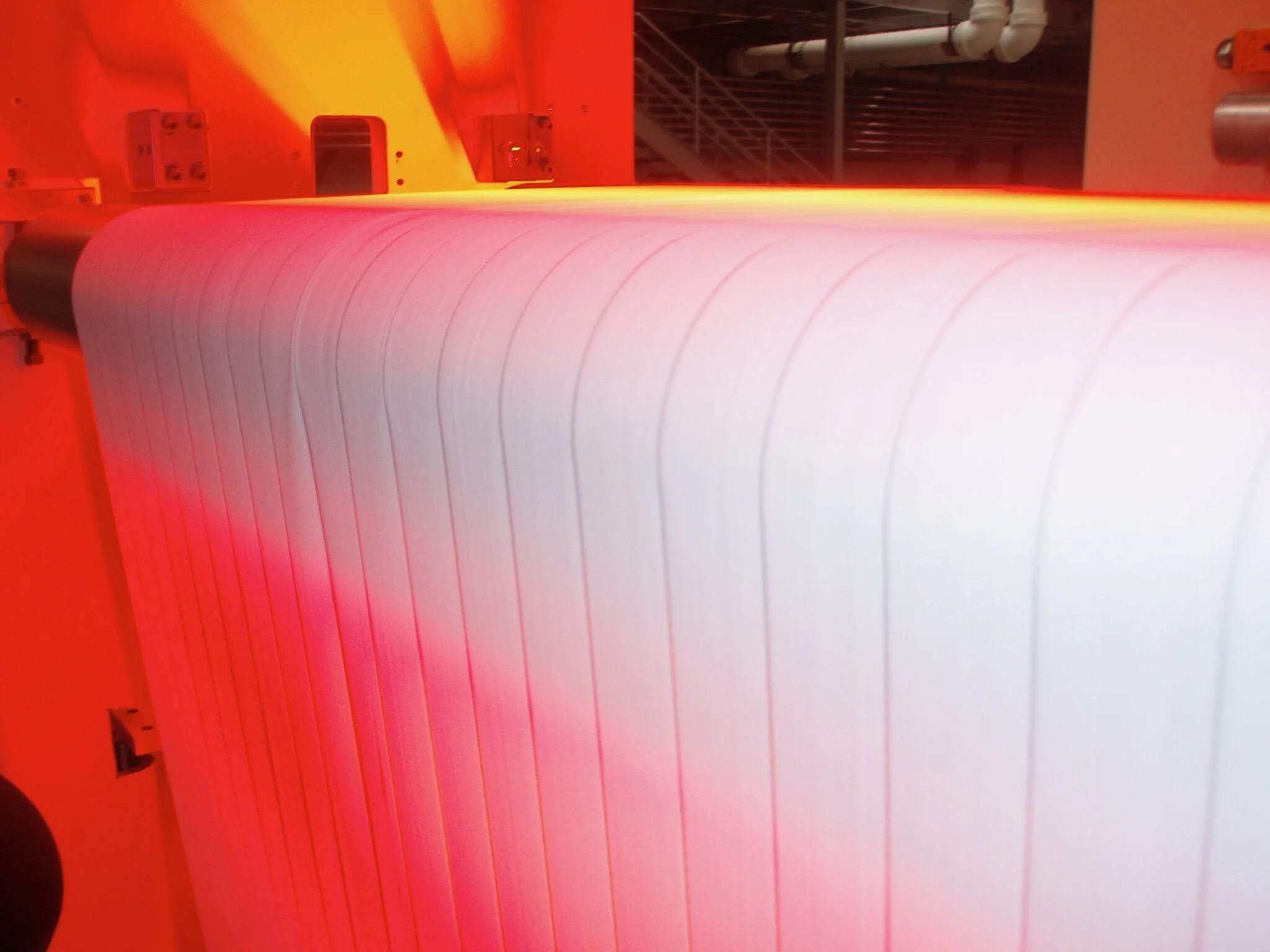

The human eye and process trained brain can combine to make an extremely powerful web inspection system. However, it has been proven in multiple industrial studies, that even experienced operations personnel become fatigued and are susceptible to distraction when asked to make historic logs of mundane/repetitive inspection tasks. The job of manual inspection and flagging of products for defects has proven to be prone to frequent errors regardless of its crucial importance in a final product’s quality certification. We provide automatic on-line web inspection systems that continuously inspect 100% of a moving material. Our automatic on-line inspection experience applies to paper, film, coating, non-woven, textile, extrusion, battery, membrane, metals, glass and other continuous web applications.

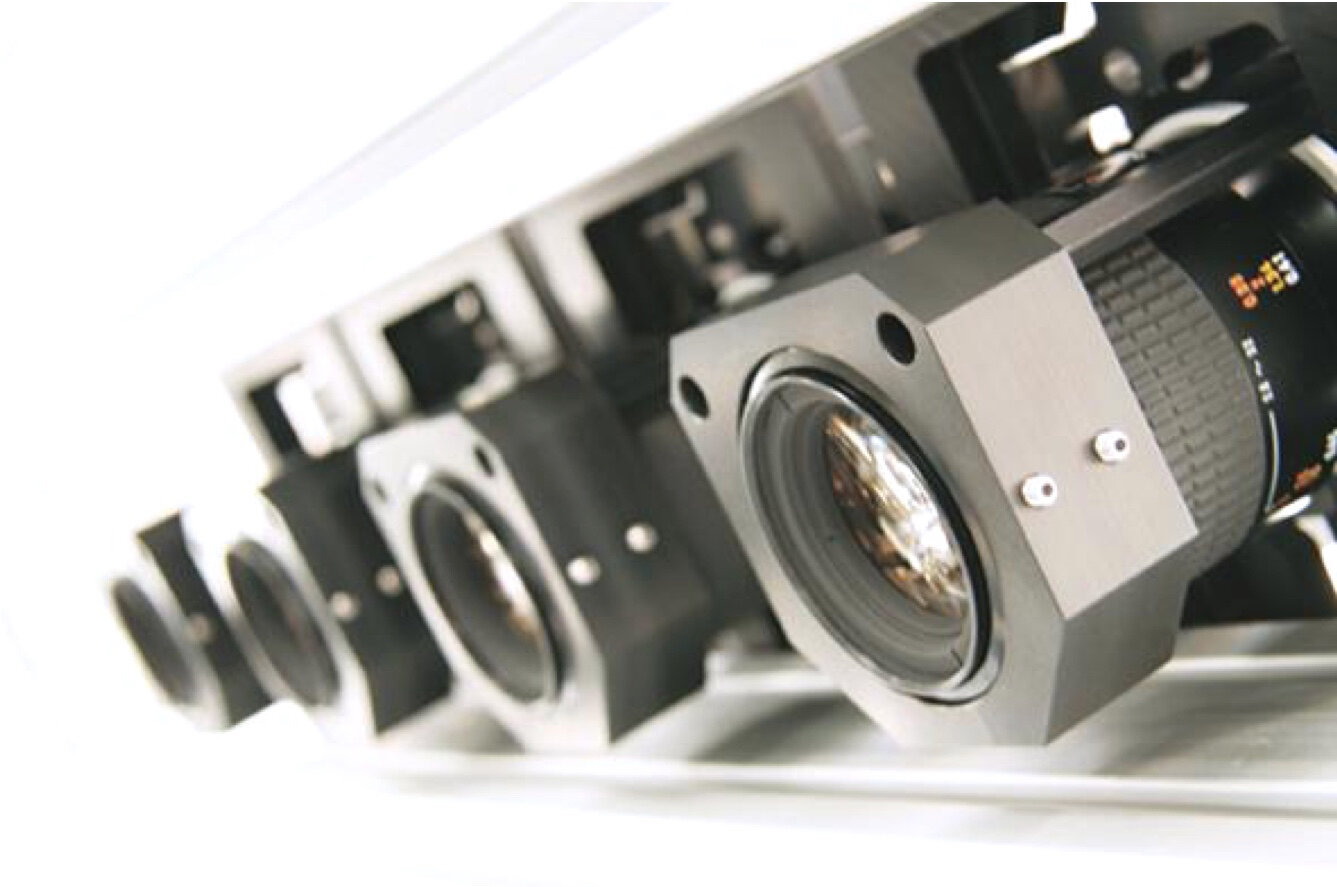

Historically, web inspection systems have used laser, cameras or hybrid combinations of sensors as their core optics technologies. Today, camera web inspection has emerged as the default solution in all but the most specialized of applications. Cameras success for web inspection applications are due to their continuously improving price performance ratio relative to other technologies – especially when the total cost of ownership is considered.

Single Camera Reflection Defect Inspection

Web inspection solutions use high-speed parallel smart camera topology to stream defect data to a central workstation to display/sort mapped images and statistics. For example, line scan camera systems are available that can provide throughput of faster than a gigapixel/second/camera. Line scan camera systems provide flexible and modular solutions in both their optical and mechanical layouts. Therefore, pixel resolutions are not fixed. Rather, they can vary based on the inspected material width, number of cameras used, and the speed of the material. While pixel resolutions of 10 microns per pixel or better are feasible, most applications actually require far lower resolutions, in the range of 50-200 microns per pixel. Line scan cameras can also readily inspect materials running at 1000 mpm (3281 fpm) or faster. The modular nature of line scan camera systems means virtually any width of material can be inspected with typical widths ranging from 50 mm (2 inches) to 4 meters (13 feet) with even wider material possible. Defect information is displayed in a convenient, ergonomic manner that is easily understood by both operator and engineering personnel. Classifiers are employed that discern and segregate defects such as holes, streaks, scratches, wrinkles, edge tears, inclusions, gels, particulates, bugs, dirt, oil, watermarks, and inconsistent formations. Defect data is readily networked, stored and evaluated in databases (e.g. SQL) by number of defects per area and/or severity levels for further production and quality analysis to provide product certification records. Defect data can also be segregated by cross web position relative to multiple slit lanes or by web direction lengths when making sheet products. Control charting options to support quality programs are also readily available. Defects can be traced by their repeat length that correlate to specific roll circumferences within the production line to assist operators with early warnings of manufacturing issues. Web marking options are available to identify defect location in a roll or sheet for future product disposition/yield analysis.

Line Scan Camera Bank

We will always attempt to offer you preliminary price range for a web inspection system after an initial discussion regarding the specifics of your application. Preliminary web inspection criteria discussed may include: web widths, line speeds, product types, defect types and level of importance, defect sizes, defect contrasts, operating environment, single or dual side inspection, marking systems and data links. For applications with a wide range of product types and/or where detection of defects with subtle optical characteristics are required, we will ask you to provide a representative defect sample set before we develop a final proposal. We will provide a complementary application report of this defect sample set that will serve to qualify and quantify inspection results for each defect type. This report will form the basis of our commercial commitment to you. Our goal is always to provide a final system deliverable that meets your expectations for results. We look forward to assisting you with your next web inspection need.