Operator Interfaces, HMI, SCADA

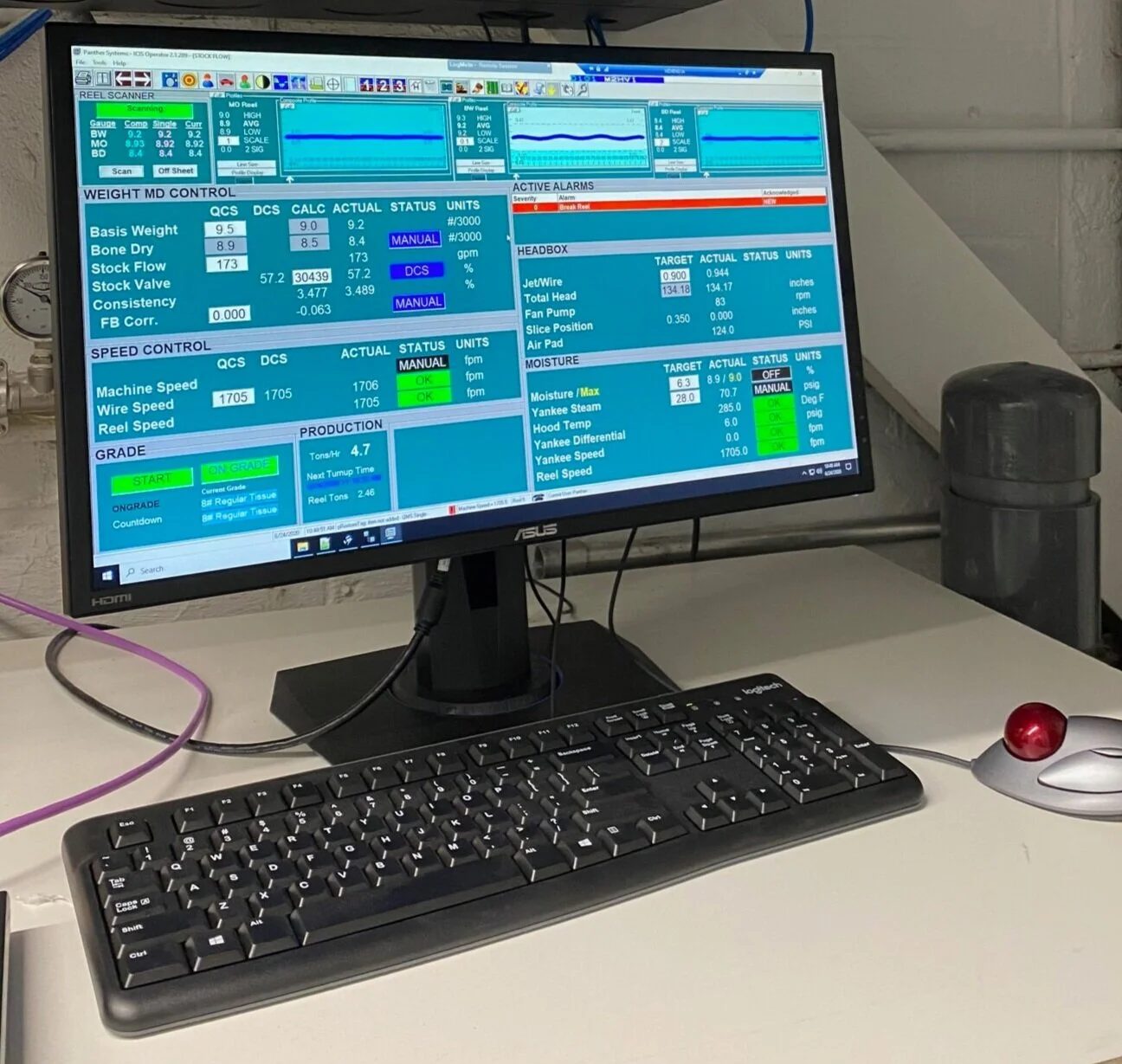

SCADA System with Gauging, Process and Logic Monitoring and Control

Industrial operator interfaces vary broadly depending upon the age, complexity and need of the line. Most all manufacturing sites will have some type of discrete potentiometer, pushbutton, switch, light and/or meter operator controls. Sometimes these controls are simply housed in small, conveniently located remote operator control stations, where the operator can see and then effect the process as necessary. Sometimes discrete control and indicators are part of central main line console where they are positioned in rows and columns. The well-designed console is made with both attention to ergonomics and line operation best suited for logical control of the process.

Today most manufacturing facilities have some type of Human Machine Interface (HMI) operator screen. HMIs come in many sizes and resolutions. They can be touch screen or non-touch screen and can be made suitable for operation in wide variety of environmental conditions. HMIs can eliminate the need for most all discrete operator controls/meters, provide pictorial representation of the line, time trend chosen process parameters and provide elementary recipe set-point control. HMIs also can simplify installation costs via replacing hardwires to from each discrete operator device with a single high bandwidth communication bus (e.g. Ethernet) to line PLCs.

Legacy Discrete Device Operator Station with HMI Touchscreen

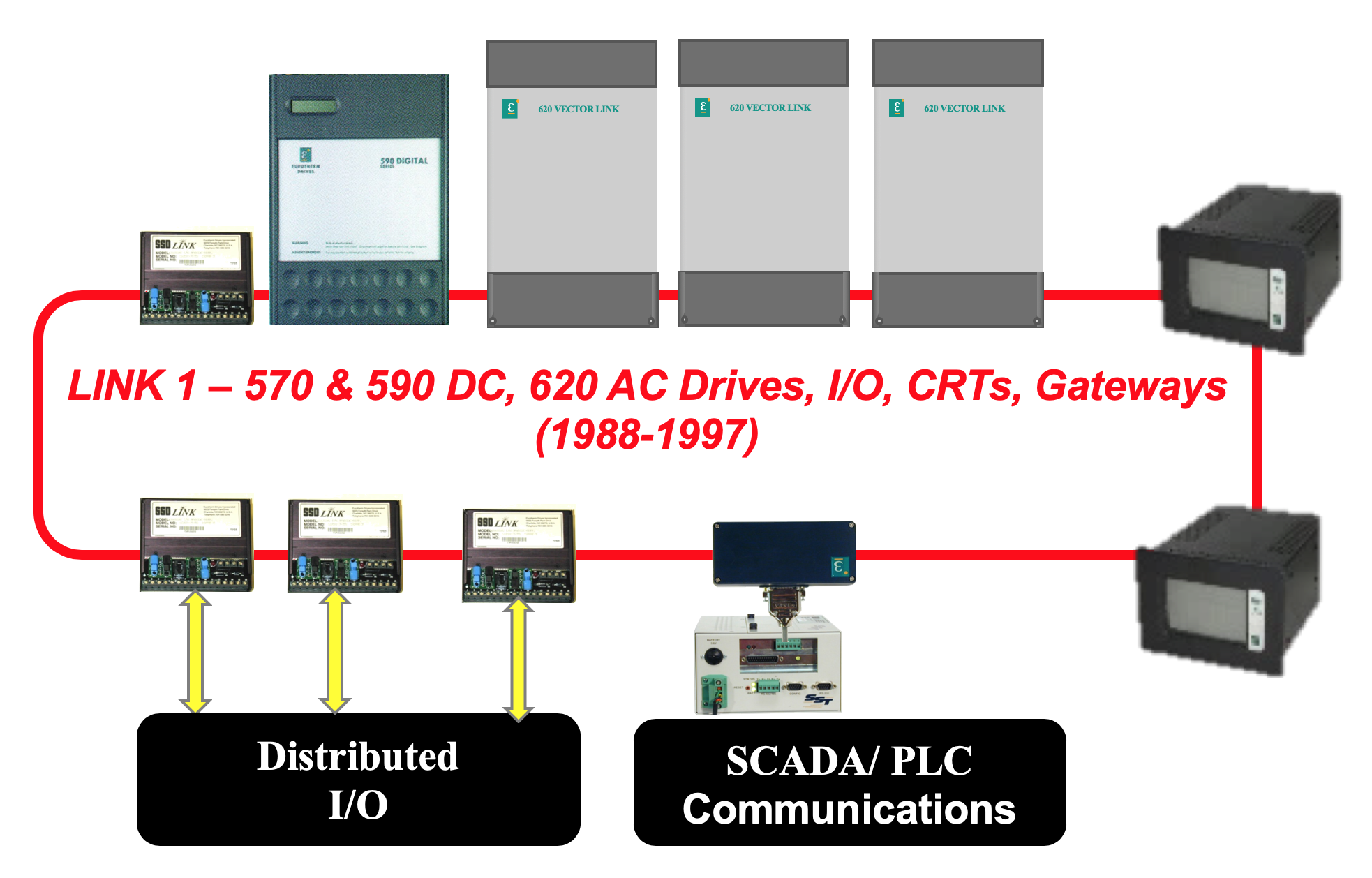

Supervisory Control Data Acquisition (SCADA) systems are used as both a operator interface, with all the same attributes of HMIs, but also the added benefits of enhanced data management and recipe control capabilities. SCADA systems are mostly Windows based and therefore conform to data interface standards (e.g. OPC) to plant process historian databases (e.g. SQL) for long term archival and retrieval of process and quality data. SCADA systems also offer many different communication drivers to translate protocols from disparate control device manufacturers (e.g. Drives, temperature, PLC, gauges, etc). The SCADA system therefore many times acts as a data hub for line. When considering upgrading operator controls for your facility please call us to discuss what makes best sense for your facility – we will be happy to offer complementary consultation in this regard.