Web Gauging

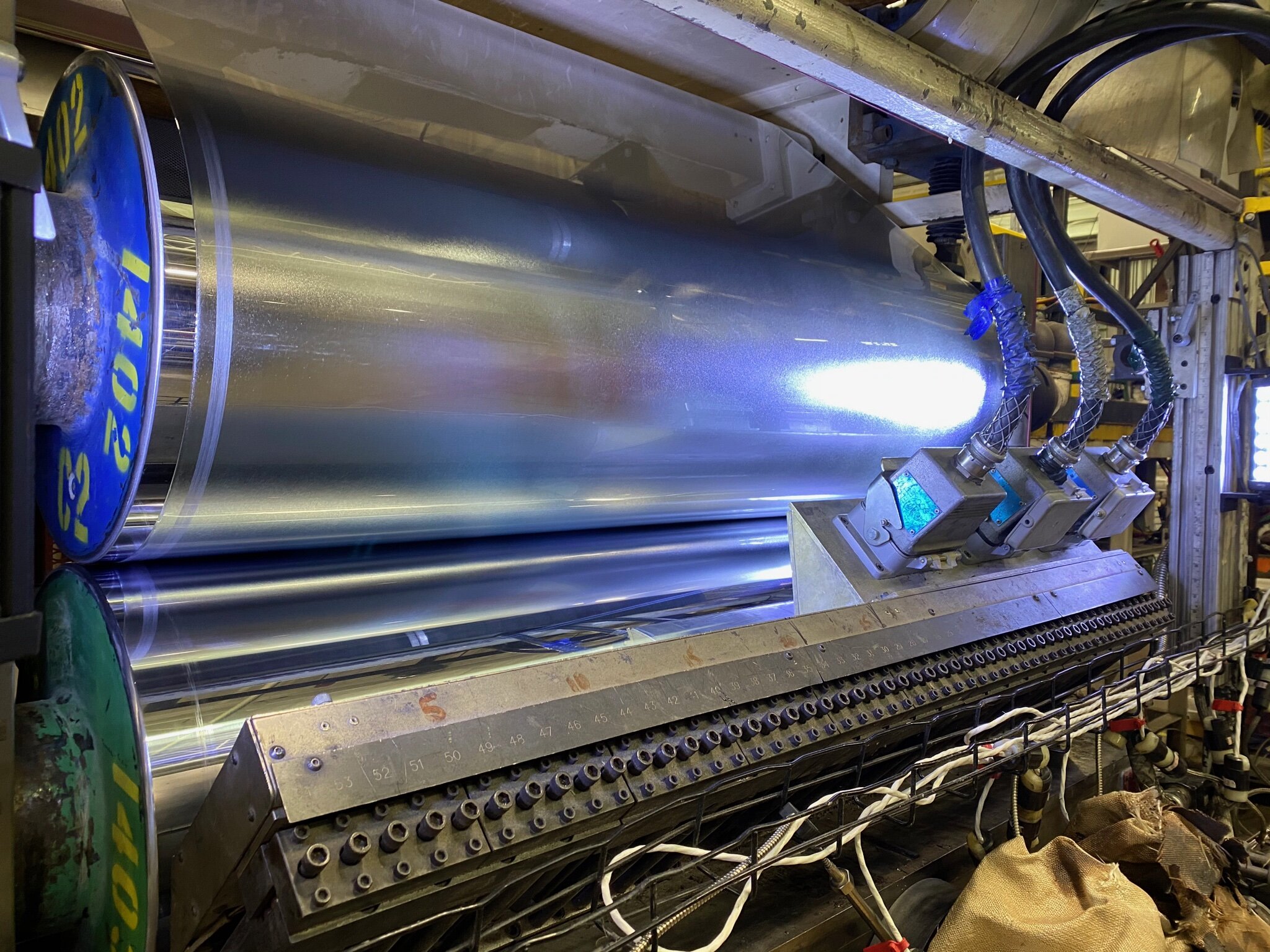

Web product measurements are the most statistically accurate when obtained with an on-line gauging system solution. Extrusion, converting, nonwovens, textile, membrane, nanotechnology, battery, solar, pharmaceutical and paper processes are just some of the markets we support with scanning gauging solutions. Certified improvements in product changeover times, scrap reduction, roll or sheet quality, product uniformity, shift repeatability, labor efficiencies and reduced material costs are all typical areas of return for a gauging system investment.

On-line measurement sensor technologies vary and can include: nuclear, laser, infrared, x-ray, interferometry and other options. The best choice(s) depends upon the customer’s specific product type(s) and measurement needs. Gross product or net coat weight, individual layer coating thickness or gross product thickness, density and moisture are the most commonly gauged but other measurement parameters are also possible.

Once a valid measurement is obtained, control can be applied to optimize the process and shift-to-shift product consistency. Automatic Profile Control (APC) can be applied through the use of adjustable die, headbox or roll height. Machine Direction (MD) control can be provided by adjusting line, pump, screw speeds or other areas where measurement feedback can affect positive control results. Target shift management can be applied to optimize your material savings while ensuring you are delivering in specification product.

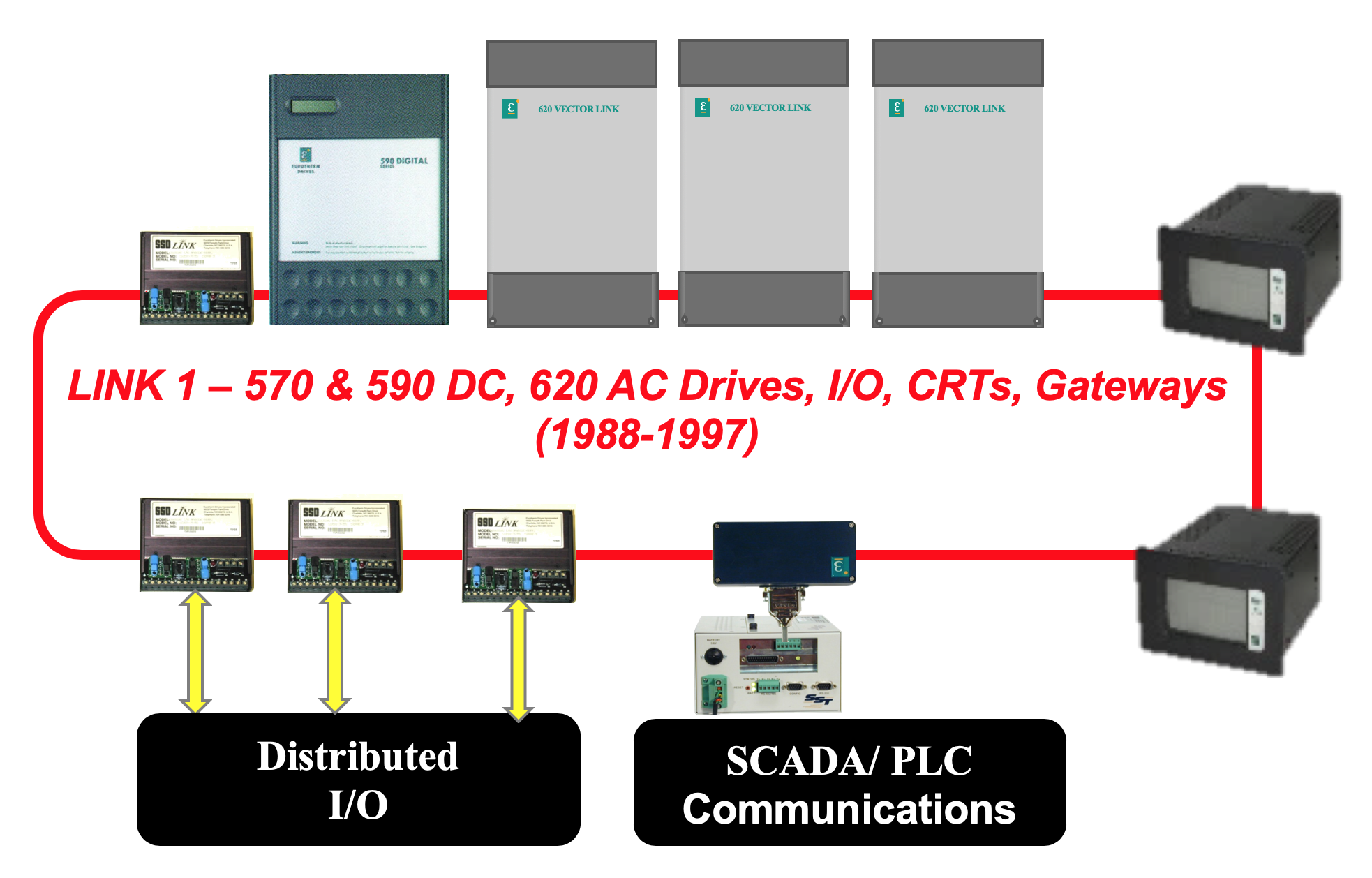

Data handshakes to PLCs, SCADA and other facility data systems are straight-forward to implement to enable features like global recipe control for various product types, early alarming for out of specification products, quality data analysis/improvements and certified histories of each roll, slit roll or sheet produced.

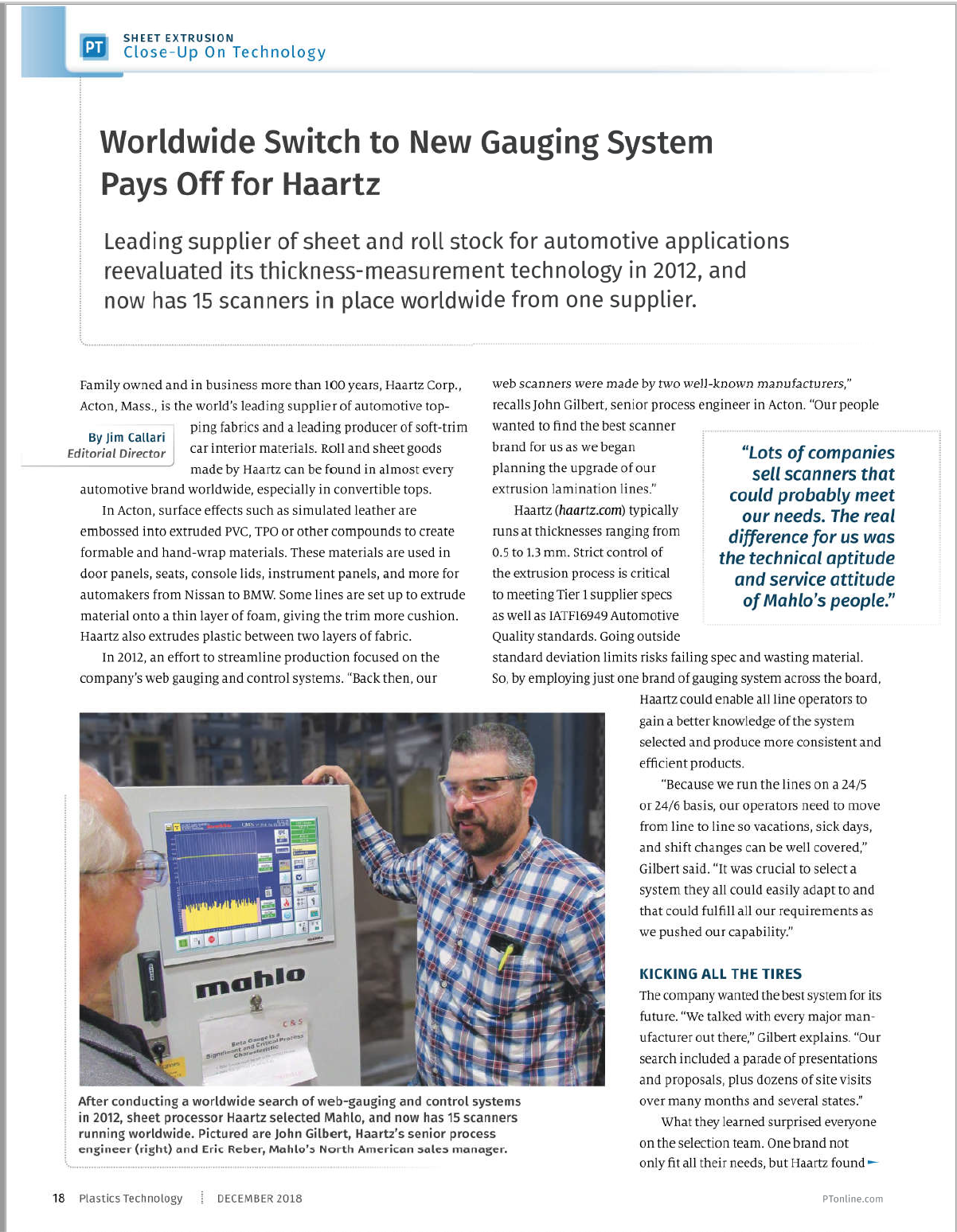

We are proud to partner with Mahlo America for web gauging solutions. Mahlo has proven to us to be the best value in the web gauging market especially when you consider their: corporate longevity (established in 1945), breadth of highly repeatable sensors, precision control offerings, robustness of scanner builds, continual research and development investment and commitment to lifetime system service and support.

Please reach out to us to discuss your application and we will organize a complementary lab trial to run your product and prove out the measurements that are of value to you.

HAARTZ CORP. CUSTOMER TESTIMONIAL

IMPACT PLASTICS CUSTOMER TESTIMONIAL

Extruder Automatic Profile Control Die

Tissue Paper Basis Weight & Moisture Gauge